That’s a Wrap- Big Picture Magazine

Time-saving tips for pre- and post-production.

AT WRAPSTAR PRO, we are a design, print production, and installation business. With that, we have developed key methods that can help save time in labor. Everything works hand in hand as a team and makes the production process flow smoothly from one step to the next with a quality end result and a very satisfied customer.

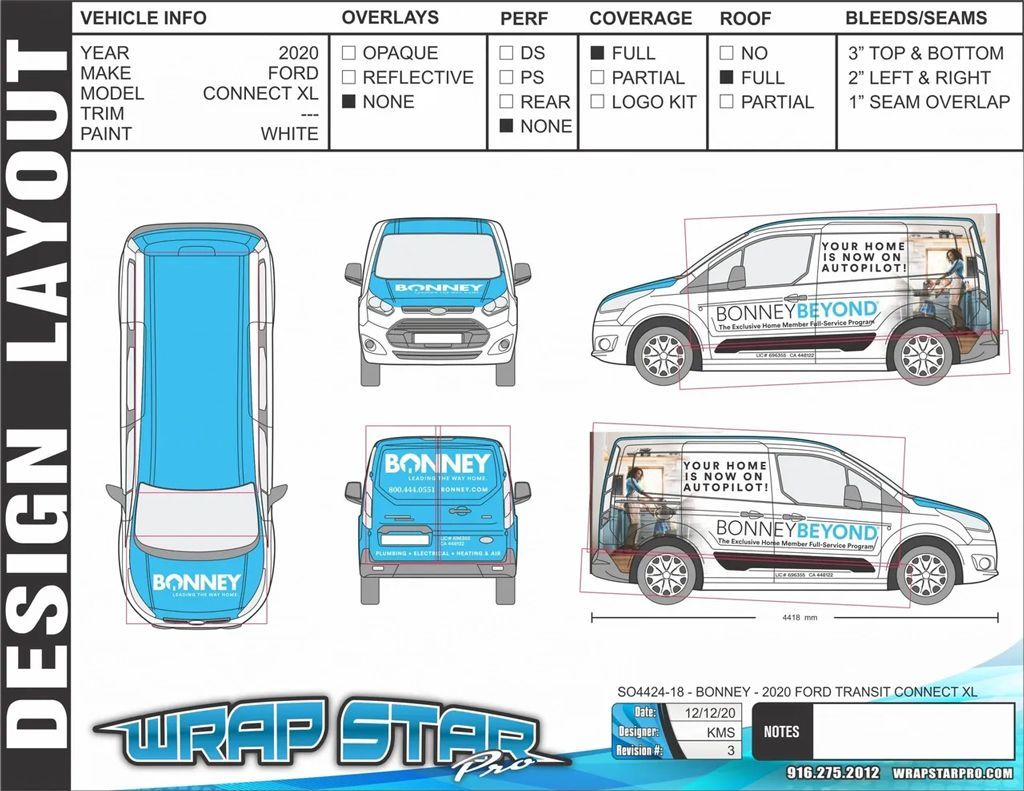

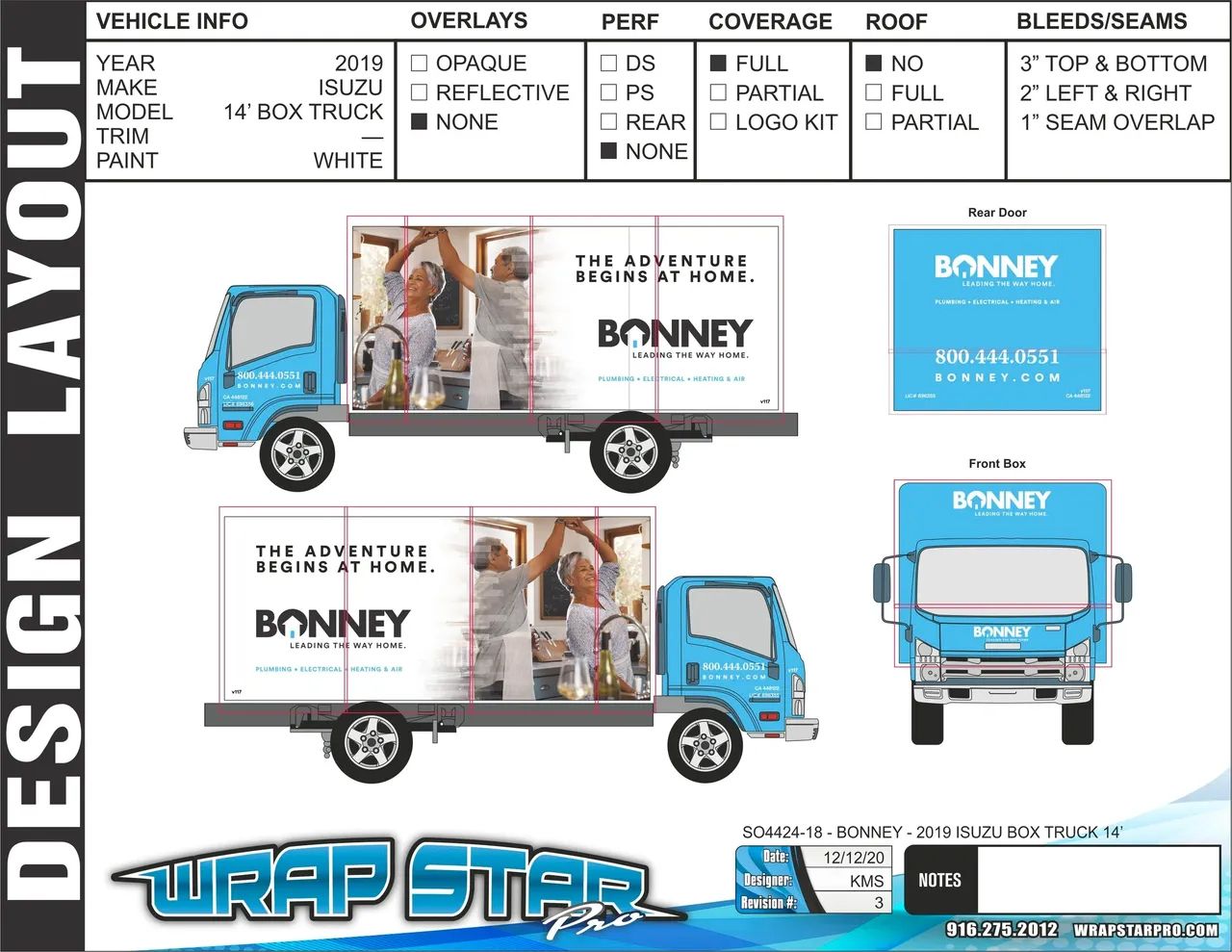

In the design process, we designate where key elements are supposed to fall by doing a rendering of the wrap layout and printing it out on paper. From there, we double check the vehicle measurements to the template and block out areas of obstruction. This is what I call creating our “safe space” for key design elements and text. For example, door handles, slide bars, wheel well areas, light areas, or any object that cannot be wrapped or have obstruction to the overall design.

Moving along to production, we designate on the wrap rendering where seams will be, how much the overlap will be, and how much bleed – or what I call “wiggle room” – is on all four sides of the print. The biggest downfall we receive from corporate graphics are lack of communication on where the print panels need to be, how much of that wiggle room is there, and the seam overlap. There are plenty of times when we receive print-and-ship graphics and the overall wrap has no bleeds built in. This comes from designer error, not adding bleeds to the vehicle template that incorporates the 3D surface, instead ending the layout to a 2D rending. When the designer and the printer lay out the instructions, this helps installers save time on prepping for the install.

Now in the hands of the installer, the best way to shave time off of the initial install will be to do some prep work on the production table before the wrap hits the vehicle. On the production table, the installer will read the instructions to understand how the panels are done. Are the panels horizontal or vertical? If they’re horizontal, the installer will pre-seam the panels together, which will make one big panel to install. Pre-seaming eliminates the struggle of aligning horizontal panels on the vehicle and making sure the bottom panel is straight and doesn’t throw off the top panel. If the panels are vertical, the installers would pre-hinge the panels with masking tape to create tabs that will assist in alignment of the next panel to the installed panel. Pre-hinging panels helps reduce time without struggling to align a 6-to-8-foot panel solo. The installer uses the tabs as a helpful tool of quickly aligning the next panel, which helps speed up the install by minutes.

If there is a hiccup from design to production to install, it makes the job harder and valuable time is wasted. If it’s done right from the beginning, as a team player, everyone wins. Don’t be that employee who cuts corners and leaves out the important elements.

View the article at https://bigpicturemag.com/thats-wrap/